How Often Should Your Commercial Backflow Device Be Tested in South Carolina?

Protecting your business’s water supply isn’t just good practice — it’s essential. Commercial backflow prevention devices play a critical role in keeping contaminants out of potable water systems. When these devices fail or go untested, businesses can face health risks, code violations and costly penalties.

Understanding how often backflow devices need to be tested — and why regular testing matters — can help South Carolina businesses stay compliant, protect customers and avoid unexpected disruptions.

What Is Backflow and Why Does It Matter?

Backflow occurs when water flows in the opposite direction than intended, allowing contaminants to enter the clean water supply. This can happen due to changes in water pressure, such as a burst pipe, heavy water demand or system shutdowns.

Commercial properties often face higher backflow risks because of irrigation systems, fire suppression systems, chemical use, boilers and industrial equipment. Without proper prevention, harmful substances can be pulled into drinking water lines, creating serious health concerns.

Backflow prevention devices are designed to stop this reversal, but they must function correctly at all times — which is why regular testing is required.

How Often Is Backflow Testing Required?

In most cases, commercial backflow devices must be tested at least once per year. Annual testing is typically required by local municipalities, water authorities and plumbing codes throughout South Carolina.

Some properties may need more frequent testing depending on:

- The type of business

- The level of potential contamination risk

- The specific backflow device installed

- Local regulations or water provider requirements

Failing to meet testing requirements can result in fines, water service interruptions or mandatory corrective actions.

Why Annual Backflow Testing Is So Important

Backflow devices contain mechanical components that wear down over time. Springs weaken, seals deteriorate and debris can interfere with proper operation. Even devices that appear to be working normally can fail internally.

Annual testing ensures that:

- The device is functioning correctly

- Pressure levels meet safety standards

- Valves are sealing properly

- The water supply remains protected

Regular testing also provides documented proof of compliance, which is often required for inspections, audits or insurance purposes.

Signs Your Backflow Device May Have a Problem

While annual testing is required regardless of performance, certain warning signs indicate your device may need immediate attention. These include:

- Water pressure fluctuations

- Visible leaks near the device

- Unusual noises during water use

- Failed inspection notices from local authorities

- Unexpected water quality issues

If you notice any of these issues, scheduling service promptly can help prevent larger problems and potential shutdowns.

What Happens During a Backflow Test?

Professional backflow testing is performed by a certified technician using specialized equipment. During the test, the technician measures pressure levels, checks internal components and verifies that the device prevents reverse flow under various conditions.

Once testing is complete, documentation is typically submitted to the appropriate water authority on your behalf, helping streamline compliance and recordkeeping for your business.

If the device fails testing, repairs or replacement may be required to restore compliance and protect the water supply.

The Risks of Skipping Backflow Testing

Skipping or delaying backflow testing puts businesses at serious risk. Potential consequences include:

- Contaminated drinking water

- Health code violations

- Fines or penalties

- Loss of water service

- Legal liability in the event of contamination

Routine testing is a small investment compared to the potential costs of non-compliance or system failure.

Why Professional Testing Is Essential

Backflow testing must be performed by certified professionals who understand local regulations and device specifications. Licensed plumbers ensure accurate testing, proper documentation and compliance with state and municipal requirements.

Professional service also helps identify aging devices that may be nearing the end of their lifespan, allowing businesses to plan replacements before emergencies occur.

Protect Your Business With Routine Backflow Testing

Clean, safe water is essential for employees, customers and daily operations. Annual backflow testing helps protect your water supply, maintain compliance and reduce risk. For South Carolina businesses, staying proactive is the best way to avoid disruptions and ensure peace of mind.

Schedule Backflow Testing With Fortner Plumbing

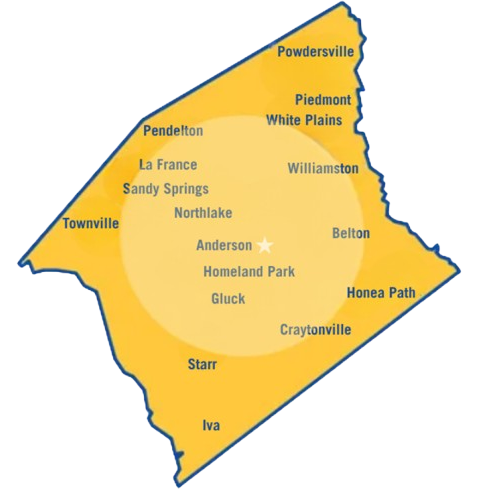

Fortner Plumbing proudly provides certified backflow testing and commercial plumbing services for businesses throughout South Carolina, including Anderson, Greenville, Pendleton and Mauldin.

Our experienced team ensures your backflow devices are tested accurately, documented properly and kept in compliance with local requirements. We also offer ongoing protection through our FlowSafe maintenance program to help businesses stay ahead of plumbing issues year-round.

To schedule your annual backflow test or request a free quote, call 864-209-0948 today. Visit our website to learn more about our full range of commercial plumbing services and how Fortner Plumbing can help protect your business.

Frequently Asked Questions About Commercial Backflow Testing

Is backflow testing required every year in South Carolina?

Yes. Most commercial properties are required to have backflow devices tested annually to remain compliant with local water authorities.

Who is allowed to test a backflow device?

Backflow testing must be performed by a certified professional with proper training and equipment.

What happens if a device fails the test?

If a device fails, repairs or replacement may be required before the system can be approved and remain in service.