Backflow Preventer vs Check Valve | What’s the Difference?

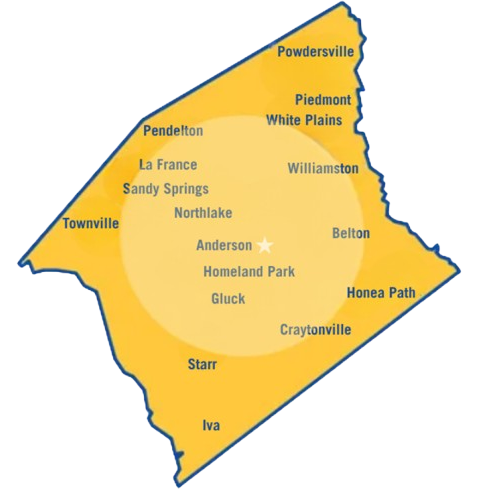

For business owners in Anderson, ensuring a safe water supply is a top priority. Whether you’re running a small restaurant or overseeing a large commercial warehouse, having a safe drinking supply is essential for everyday operations.

You may be familiar with backflow prevention testing but you might not know its exact function – or that there are two types of valves used to keep local water supplies safe: backflow preventers and check valves. Understanding the difference between a backflow preventer and a check valve is key to ensuring your plumbing system is both safe and compliant with local codes.

Failing to use the correct device or to have it inspected regularly could result in contaminated water, regulatory fines or costly plumbing repairs for business owners down the line. Let’s take a look at backflow preventers and check valves to see how they protect Anderson’s water supplies.

Backflow Preventers and Their Purpose

Backflow preventers are devices designed to keep contaminated water from reversing direction and entering the clean water supply. Normally, wastewater flows in a single direction – from our homes to the municipal or county water mains.

However, if the pressure in the water main decreases, water can reverse direction and flow back into the home, potentially contaminating the clean water supply. Backflow preventers stop this from happening by blocking the return of dirty water.

Check Valves

Check valves are responsible for ensuring that water flows in one direction. Similarly to backflow preventers check valves help to prevent contamination by stopping polluted water from flowing back into clean water.

So, What’s the Difference?

While their objectives are similar, there are some key differences between back flow preventers and check valves. Backflow preventers are more complex than check valves. They can also release water or divert water to prevent contamination from occurring. Check valves

only

prevent water from flowing in a certain direction.

Check valves are used in HVAC systems and in water treatment plants. These are typically used in low risk situations where contamination won’t seriously compromise the health of others. In contrast, backflow preventers are placed in areas where contamination is possible. They are primarily used to protect drinking water and irrigation systems. It’s typical to find them in places like commercial buildings and fire sprinklers.

Why Do We Not Just Use Backflow Preventers All the Time?

Backflow preventers aren’t always used, particularly in situations where the risk of contamination is low. This is mainly due to factors like:

Cost

Since backflow preventers are more complex, they cost more to install and require more maintenance than check valves. To comply with safety regulations, backflow preventers must be frequently tested to ensure they are preventing contamination from occurring.

Water Hammer

This phenomenon occurs when water pressure suddenly changes, forcing water to bounce rapidly inside the pipe. While backflow preventers don’t directly cause water hammer, they can make the effects stronger since they force water to flow in one direction. To mitigate the impact of water hammer, check valves may be used instead of backflow preventers.

While They Differ, Both Require Regular Maintenance

Check valves and backflow preventers need routine maintenance to ensure they function properly and protect water systems from contamination. Over time, debris, wear or mineral buildup can impair their ability to fully close, allowing water to reverse its direction.

Regular inspections and testing can identify underlying issues before they become bigger and compromise the safety of others. Maintaining these devices not only ensures compliance with health regulations but also extends their operational lifespan, saving time and hassle in the long run.

Contact a Professional Plumber

Routine inspections should be done by a professional plumber. A licensed plumber has the training and experience to properly evaluate these devices, identify potential issues and make the repairs needed to ensure check valves and backflow preventers are functioning as intended.

Backflow prevention testing, in particular, must be done by a professional plumber. If backflow preventers are not tested correctly, contaminated water could enter the water supply and make people sick. Additionally, these devices are complex in design and require specialized knowledge to perform safe and effective maintenance.

Ready To Get Started? Contact Fortner Plumbing Today!

If you’re an Anderson business owner looking for reliable repair and testing services, Fortner Plumbing is eager to help! Give us a call at 864-209-9948 to learn more about our backflow prevention and testing. For more information about our other services including safety and testing, visit our website by clicking the link

here.